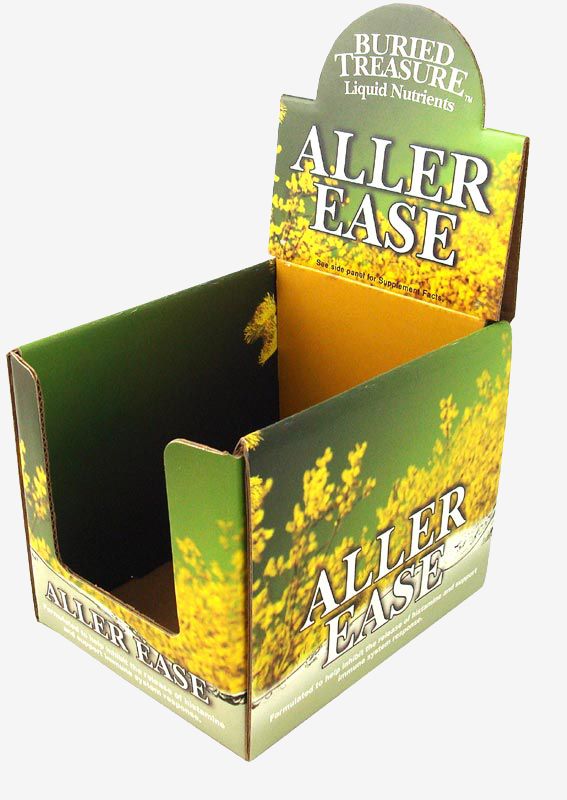

A wholesale display box is a great way for a brand to market a new product. It provides a designated location where shoppers can get a glimpse of the new offering, with promotional messaging designed to tempt them into giving it a try. These displays help provide a distinct showcase of a new product away from its competitors on the regular shelving. Given the unique way in which this merchandise is being presented, it is important to take extra steps to ensure safety, especially if the items on display are of high value.

Ensure good lighting

Ensure that wherever you place the display, it is a well-lit area. Even if it is a wholesale counter display, make sure that there is good visibility and illumination so that staff can easily keep an eye on what is happening around that area. You can even strategically place some mirrors to avoid blind spots.

Keep staff alert

Staff should be reminded to keep an eye on new displays. With a product that is likely to attract plenty of attention, it can be a good idea to have some salesperson or merchandiser on hand to answer questions from prospective customers that mill around a wholesale display box. They should not be too obvious or seem to be monitoring customers. Many shoppers dislike the feeling that they are being followed around a store. As they keep an eye on the display, they should also try to keep their presence as much as possible in the background to avoid making shoppers feel uncomfortable that they are being monitored.

Use display locks

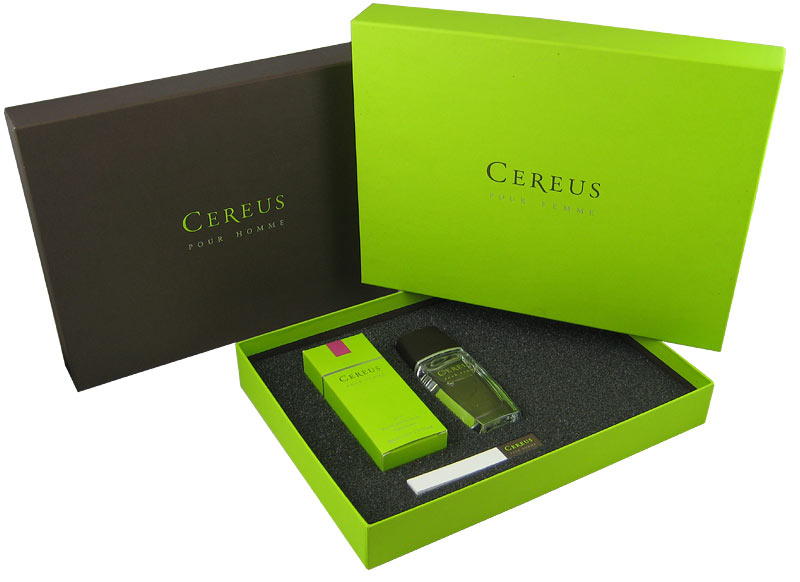

Display locks like peg hook devices allow for shoppers to see and even touch products on display, but not actually remove them from the display. This can be a good way to reduce the risk of theft or damage to items that are prone to theft or injury. You can even have your wholesale counter display customized with a lockable acrylic enclosure. This can be a good option for high-value items you want prominently displayed but not accessible to customers unless under the supervision of an employee.

Wholesale counter display surveillance

Setting up your display in an area where you can have surveillance cameras monitoring is another way to safeguard the merchandise on display. To further ensure that even bad elements are discouraged from attempting any theft or damage, you can even put up signage around the area warning that it is being surveilled. The use of product tags that set off alarms if taken through electronic sensors is another form of surveilling.