Custom labels are a great addition to product packaging when sending out orders. They are a good way to convey different messages to customers on receiving their packages and can even be used to better secure packaging. They are distinct and will often draw the eye of an observer, making them also ideal for branding purposes. More so when you pick unusual or colorful designs. however, to properly capitalize on this marketing opportunity, it is important to ensure you adhere to these tips.

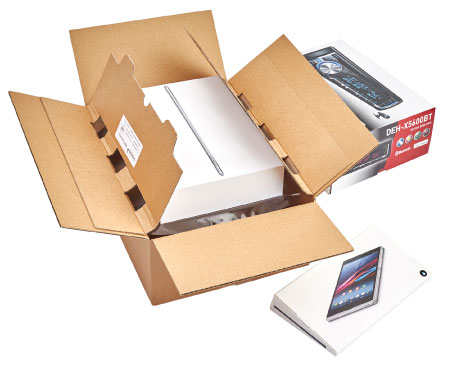

Quality Materials

When designing custom printed labels, it is vital to ensure the materials are of good quality and are in keeping with the rest of the packaging. It can reflect badly on your brand if the label you apply is of poor quality and arrives damaged at its destination.

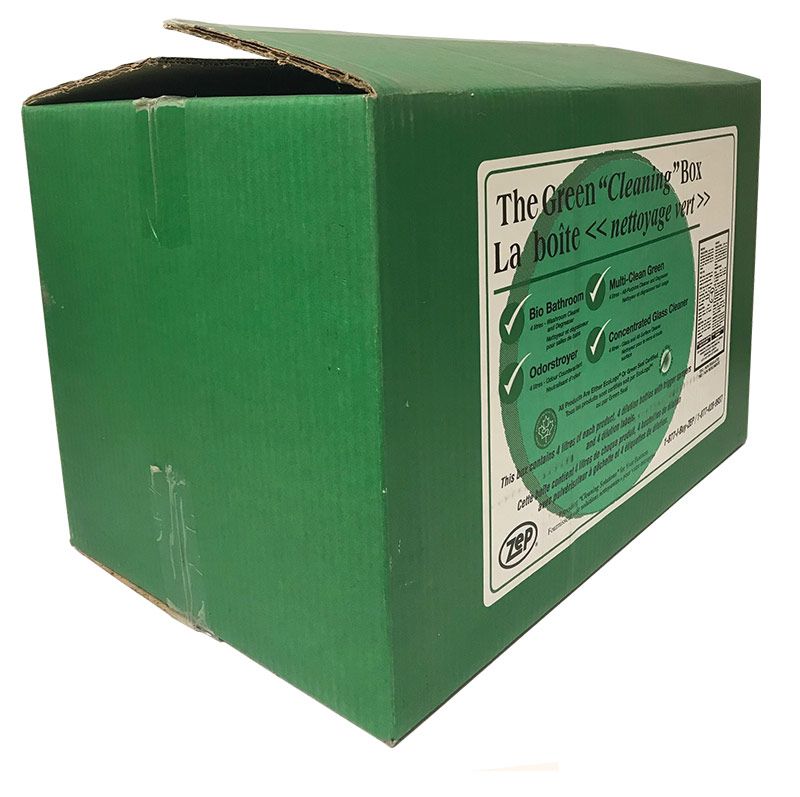

Color

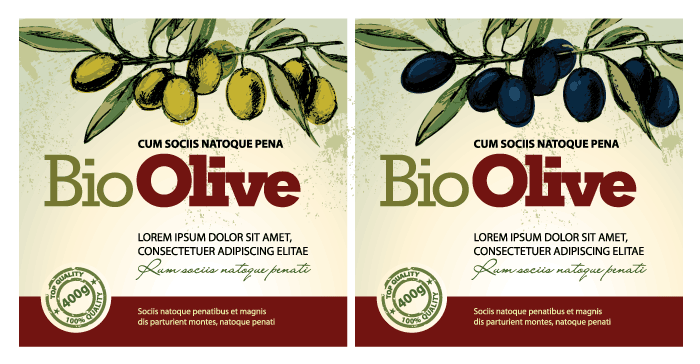

As said, a colorful custom label is great for attracting attention when you want it. Avoid plain black and white designs that often go unnoticed and are therefore a waste of money to invest in. before you can share a message with observers, you need them to be able to notice the label. Thankfully, many providers offer a full range of color options that can be made glossy for even better results.

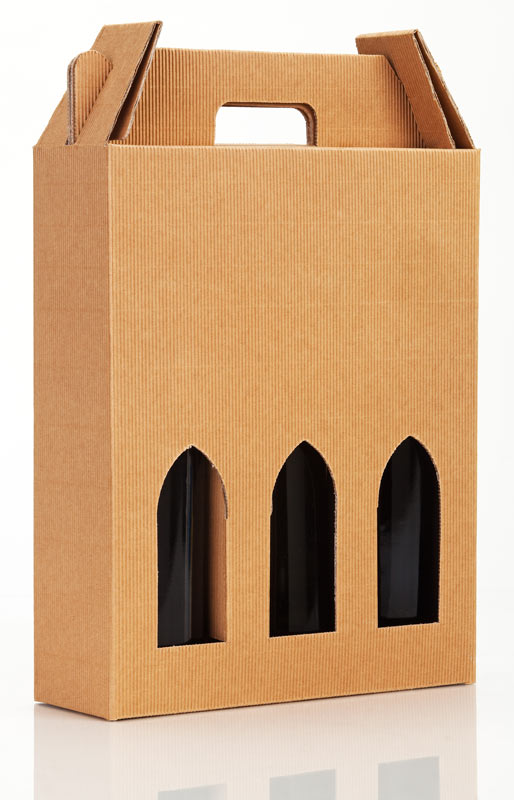

Shape

You may opt to use custom labels with basic designs like rectangular or circular shapes. However, it can be worthwhile and just as affordable to opt for more creative shapes and sizes that will combine with attractive coloring to draw the attention of whoever sees it. The more unique the overall design, the more curious a person will be to take a closer look and find out what message is being shared.

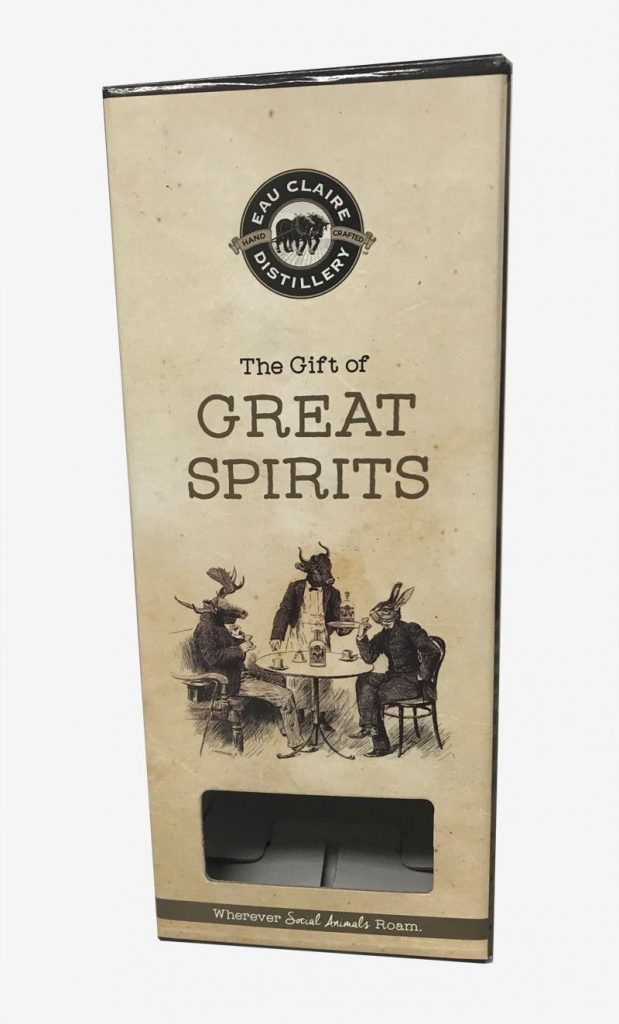

Message

Labels are not typically that large and are designed to briefly hold the attention of an observer and share a message. The message should therefore be brief. Sticking to a short but sweet message is the best way to get your message across without boring the observer and causing them to lose focus. It is also important to proofread the message. Spelling mistakes can again reflect badly on your brand and in this age of social media, can result in your going viral for the wrong reasons.

Imagery

It helps to pair your written message with colorful imagery that is captivating to look at. Whether it is a cartoon or hologram, choose a visual lure that will make it more worthwhile for an observer to take a closer look at your custom label.